Customized Stop-the-Slip Solutions

For Your Unique Conditions

Many homes include ramps to allow access for loved ones using wheelchairs or mobility scooters. Sometimes these ramps are constructed of concrete, which can present unique slip and fall hazards.

Your Stop-the-Slip Solutions Graded:

HandiTreads: A-

HandiTreads are the most effective and long-lasting solution for minimizing the risk of slips and falls on concrete ramps. Because the ramps are inclined, they can encourage slips and falls especially when external conditions like rain, sleet, or snow are present.

HandiTreads provide exceptional grip on concrete ramps under even the most challenging conditions. The pressure from a foot stepping on the rigid raised buttons pushes away the layer of moisture, frost, or up to an inch of snow, creating solid contact between the tread and shoe. HandiTreads prevent slip, trip, and fall accidents year-round and in all weather conditions.

As noted in our installation instructions, the installation of HandiTreads is exceptionally user-friendly. The only variation from the linked installation instructions is that concrete lags must be used for installation on concrete surfaces. Once installed, HandiTreads do not require any further maintenance and are guaranteed to last a lifetime at your home.

If it snows, you can use a snow shovel (without a steel edge) to easily clear your HandiTreads from deep snow without fear of damaging the treads. This is not the case with grit tape, rubber mats, or even anti-slip paint that may become damaged when in contact with a snow shovel.

The initial cost to fit a concrete ramp with HandiTreads will be higher than less effective and less durable alternatives, but the payback will come quickly in the form of less maintenance and substantially longer product life. We recommend spacing the treads four inches apart but have seen successful installations with longer intervals. Using four-inch spacing, a 5-foot ramp would require approximately 15 treads.

When the value of HandiTreads is calculated over just a three to five year performance period, the investment in HandiTreads is often the most cost-effective solution.

Total Score: A-

Effectiveness: A

Installation & Maintenance: A

Durability: A

Initial Price: C

Long-Term Value: A

Non-Slip Grit Tape: D

Anti-slip tape cannot be used on bare concrete because the surface cannot be sufficiently cleaned and the adhesive will quickly fail as the concrete allows moisture to seep up through its surface, degrading the paper-backed tape. Grit tape can be used on some sealed or painted concrete ramps as a short-term fix to reduce slips and falls due to rain or light frost. However, grit tape is not effective in snowy weather.

Generally speaking, grit tape does not have any possible maintenance. Once it loses efficiency, there is nothing a homeowner can do to restore its non-slip properties. Snow removal from the tape can also be a real challenge as a snow shovel can easily pull up the tape from the concrete surface. The inability to do more than brush snow off non-slip tape makes it useless once the snow becomes compacted and frozen to the ramp.

The proper installation of Non-Slip Grip Tape requires more effort than perceived because of the surface preparation required. It is critical that the smooth-painted or sealed concrete surface be clean, dry, and in good shape. If the cement is cracking, the grit tape will not apply properly. Once the surface preparation is complete, it is crucial that the installer make sure that the grit tape is applied without bubbles, which could affect the tape’s efficacy.

Grit tape can be an inexpensive yet temporary solution if you are content with a grit tape lifespan of six months to a year on your outdoor cement ramp.

Total Score: D

Effectiveness: D

Installation & Maintenance: C

Durability: F

Initial Price: A

Long-Term Value: D

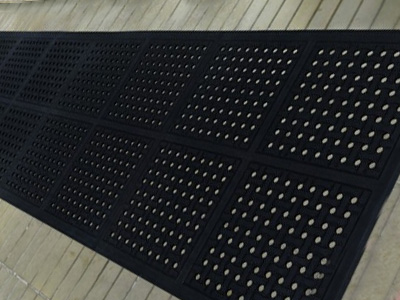

Heavy Duty Rubber Runners: C-

Heavy-duty rubber runners can be eyesores on concrete ramps and tend to catch and collect dirt over time. However, the runners can be an effective, temporary way to increase the traction on a concrete ramp. Conversely, the more aggressive the tread or traction pattern on the runners, the more difficult it will be for wheelchair users to climb the ramp.

While rubber runners handle moisture with ease, they must be kept free of snow if they are to be effective in the winter. The channels or cutouts that provide traction in wet conditions can also hold ice and snow. If ice collects within the rubber runners, it can turn the rubber tread into a slip and fall hazard in itself.

Care must be taken when using a snow shovel with rubber runners as even a plastic blade can cut the rubber. Snow is best removed from the heavy-duty rubber runners by picking them up off the concrete ramp and shaking the snow off. This procedure must be repeated several times during heavy snow, increasing both the time and cost required to use them as a slip-and-fall solution. Rubber mats must also be cleaned fairly frequently as dirt and debris are easily caught and captured in the grooves or holes that provide traction and drainage.

There is no installation required with mats as they can be laid down in the area where you need the extra traction. Depending upon the thickness and quality of the rubber mat material you can expect the mat to last only about 2 to 4 years on your concrete ramp.

Total Score: C-

Effectiveness: D

Installation & Maintenance: D

Durability: C

Initial Price: B

Long-Term Value: C

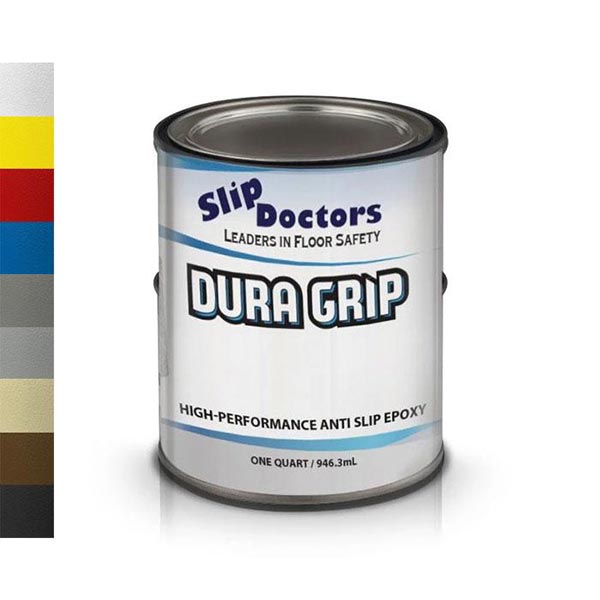

Grit Paint: B+

Grit paint is an excellent way to reduce slip and fall hazards on both bare concrete and finished concrete ramps. A high-quality grit paint, like Slip Doctor’s Dura Grip and Tuff Grip epoxy paints, can greatly improve the safety of a concrete surface if it’s applied meticulously and maintained properly. Like grit tape, non-slip paints include an aggregate that creates traction. The best anti-slip paints contain aluminum oxide or carborundum that are encapsulated in the paint and create a coarse, slip-resistant surface. Grip paint can be effective for wet weather, frost, and light snow.

The quality of the paint used and proper application is critical to the longevity of anti-slip paint. If the concrete is in good shape, cleaned, and prepared properly, and the paint is applied as instructed, you can anticipate that grit paint will last 3 to 5 years under normal consumer traffic.

Anti-slip paints on exterior surfaces are, by and large, maintenance-free. However, if you live the receives a lot of snow in the winter months, you need to be very careful not to aggressively shovel the ramp painted with grit paint. While the epoxy or enamel coating is durable under normal foot traffic, it’s no match for an aluminum snow shovel. Once you start to scrape away the thin paint layer covering the aggregate, the anti-slip system will quickly degrade.

The cost of a high-quality grit paint can run between $120 and $160 a gallon. In addition, you’ve got the consumable cost of paintbrushes or rollers, trays, sandpaper, masking tape, and drop cloths. When all costs are factored in, and depending upon the length of the ramp, grit paint can be a cost-effective solution, even with the need to repaint.

Total Score: B+

Effectiveness: A

Installation & Maintenance: C

Durability: B

Initial Price: A

Long-Term Value: B