Customized Stop-the-Slip Solutions

For Your Slippery Ramp Conditions

Many homes include wooden ramps in order to make entrances more accessible for loved ones in wheelchairs or mobility scooters. However, even if you’re just walking, the smallest incline can encourage slips, trips, and falls. Added environmental conditions like rain, sleet, or snow can create an incredibly slippery condition on any ramp at home or at work.

It is crucial to prevent slip, trip, and fall accidents before they happen. Don’t wait until an injury occurs on your wooden wheelchair ramp to start applying safety measures. Your four graded options below will outline the solutions best suited for the outdoor wooden ramp at your home.

Your Stop-the-Slip Solutions Graded:

HandiTreads Deck Treads: A

No matter the size or purpose of your wooden ramp, HandiTreads Deck Treads will make your ramp non-slip in any weather. With a Deck Tread attached to each board, every step is guaranteed to maintain firm contact with the patented raised traction buttons.

While gentle on bare feet and pet paws, the traction buttons dispel debris, moisture, frost, or snow, creating solid contact between the tread and shoe. Unlike grit tape or paint, you can even use a snow shovel to clear snow from the Deck Treads!

Installation of the aluminum HandiTreads Deck Treads is simple. Each Deck Tread comes with color matching and self-tapping screws that make quick installation work. No surface preparation is required before installing the Deck Treads and no maintenance once installed. Of course, the treads are covered by our lifetime residential warranty.

HandiTreads Deck Treads are available in four designer shades to complement the color of any stain or finish on your ramp. The deck treads will either blend in with the wood or create an appealing contrast. They’re the perfect combination of safety, value, and home design!

Because our Deck Treads are often used to cover large spaces, we’ve made them affordable by offering them in packs of 10 for just $144 with free shipping. To offer this price, you can only find the Deck Treads in our online store.

Total Score: A

Effectiveness: A

Installation & Maintenance: A

Durability: A

Initial Price: B

Long-Term Value: A

HandiTreads Stair Treads: A-

If you’re looking to maximize safety and you’re less sensitive to appearance and price, HandiTreads stair treads, like deck treads, are the most effective and long-lasting solution for minimizing the risk of slips and falls on wooden ramps used for wheelchair access.

HandiTreads stair treads work exceptionally well on long wooden ramps because they provide outstanding grip under even the most challenging conditions. The pressure from a foot stepping on the raised traction buttons pushes away the layer of debris, moisture, frost, or up to an inch of snow, creating solid contact between the tread and shoe.

Installation of the aluminum HandiTreads is simple, as described in the installation instructions. Unlike grit paint, there’s no need for time-consuming and messy surface preparation. Once installed, no maintenance is required for HandiTreads which are guaranteed to last a lifetime in your home and for a year in commercial settings.

HandiTreads are available in four refined earth-toned shades that match popular colors of wooden ramps. The treads can either blend in with the wood of your ramp or create an appealing contrast in shades, making them the perfect anti-slip solution for homeowners who value both safety and home design.

The initial cost to fit a 10-foot or longer ramp with HandiTreads can be substantial, depending upon your budget. We recommend spacing the treads at eight inches apart, or every other board. Using 8-inch spacing, a 10-foot ramp would require approximately 15 treads.

Because HandiTreads are a lifetime solution with once-and-done installation and maintenance, the initial investment may be higher than other non-slip solutions. When calculated over a three to five year performance period, however, the investment in HandiTreads is often the most cost-effective solution.

Total Score: A-

Effectiveness: A

Installation & Maintenance: A

Durability: A

Initial Price: C

Long-Term Value: A

Non-Slip Grit Tape: D-

For the most part, grit tape available at Home Depot or Amazon is not appropriate for outdoor use. There is no tape-based adhesive that can realistically stand up to rain, snow, and the inevitable heat and thaw cycles.

In a limited number of outdoor wooden ramp situations, non-slip grit tape can be a short-term solution to reduce slips and falls. Rain and frost are easily mitigated by the grit embedded into the tape. However, grit tape is not able to increase traction in snow. You also cannot use a snow shovel on grit tape. Not only will you pull the tape right off of the ramp if you catch an edge, but even a plastic blade will quickly degrade the thin coating protecting the aggregate.

The proper installation of non-slip grip tape does require a bit of effort as detailed here. First, it’s important that the wood surface, whether stained or painted, is clean, dry, and in good shape. Heavily grained, uneven, or splintering wood makes it difficult for the tape adhesive to completely bond. The effective life of grip tape is directly related to how carefully and completely it has adhered to the steps.

There’s no maintenance that can or should be done to the tape other than to be very careful of the edges and corners, which can be easily pulled up. Once a corner or edge begins to peel, the grip tape will quickly deteriorate.

If you’re comfortable with a lifespan on outdoor wood of six months to a year, grit tape can be an inexpensive temporary solution.

Total Score: D-

Effectiveness: D

Installation & Maintenance: C

Durability: F

Initial Price: A

Long-Term Value: F

Grit Paint: C+

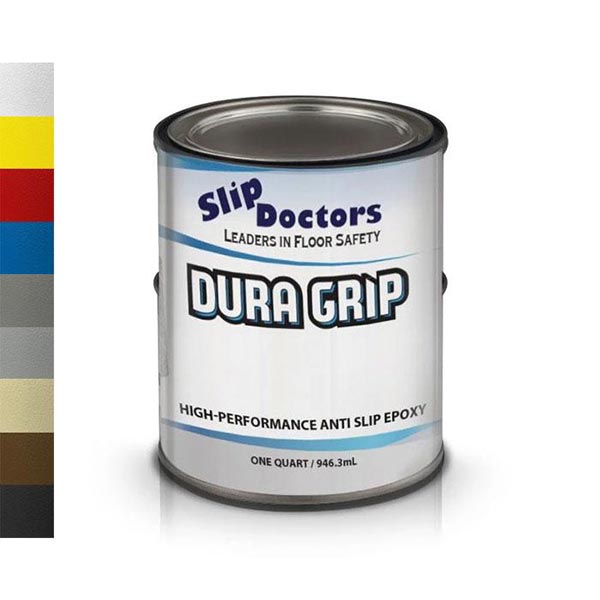

A high-quality (NOT Big Box Store) grit paint can improve the safety of a long, wooden outdoor ramp. It’s critical that you choose a top-notch grit paint like the Slip Doctor’s Dura Grip and Tuff Grip traction paints, that they are applied well, and that the paint is maintained properly. Like grit tape, non-slip paints include an aggregate that creates traction. The best anti-slip paints contain aluminum oxide or carborundum that are encapsulated in the paint, creating a rough, slip-resistant surface. We rate the effectiveness of grip paint very high for wet weather and frost, but it’s ineffectual with snow deeper than an inch.

Longevity is another challenge with anti-slip paint when used on a wooden ramp. The incline of the ramp creates much more pressure between shoes and, more often than not, the wheels of wheelchairs and mobility scooters. This increased pressure leads to a shorter life and the need to repaint the ramp after two to three years.

There is no maintenance that can be performed on anti-slip paints other than regular sweeping. However, if you live in a location that receives snow, you need to be very careful not to aggressively shovel a ramp painted with grit paint. While the epoxy or enamel coating is durable under normal foot traffic, it’s no match for an aluminum snow shovel. Once you start to scrape away the paint layer covering the aggregate, the system will quickly degrade.

The cost of a high-quality grit paint can run between $120 and $160 a gallon. In addition, you’ve got the consumable cost of paint brushes or rollers, trays, sandpaper, masking tape, and drop cloths that will likely cost an additional $40. However, the longer the ramp, the more efficient the application of grit paint which reduces its initial cost while enhancing the paint’s long-term value.

Total Score: C+

Effectiveness: B

Installation & Maintenance: D

Durability: B

Initial Price: C

Long-Term Value: C