Customized Non-Slip Solutions

For Your Concrete Steps

Reducing Slips and Falls on Concrete Steps

HandiTreads compares four proven solutions for preventing slips on concrete stairs—non-slip nosings, aluminum treads, rubber mats, and grit paint—ranking each by effectiveness, durability, and long-term value.

Concrete stairs may seem safe, but they become dangerously slick when exposed to rain, ice, snow, or debris. This guide breaks down the most common non-slip solutions for concrete steps—including aluminum nosings, HandiTreads, rubber treads, and grit paint—so homeowners, contractors, and property managers can make an informed decision about the most effective and permanent way to prevent slip-and-fall accidents outdoors.

Your Stop-the-Slip Solutions Graded:

Solution | Effectiveness | Maintenance | Durability | Initial Price | Long-Term Value | Best For |

Aluminum Non-Slip Nosings | A | A | A | c | A | Concrete steps with chipping or cracking edges |

HandiTreads Aluminum Treads | A | A | A | C | A | High-traffic or weather-exposed stairs |

Rubber or Doormat-Style Treads | C | D | C | B | C | Temporary or indoor concrete steps, like garages |

Grit Paint | B | C | C | B | C | Small concrete porches or short-term fixes |

Aluminum Non-Slip Nosings: A-

When covered with water, ice, or snow, the edge of concrete stair treads can become a slippery trip and fall hazard. Aluminum non-slip nosings prevent slips and falls by providing a reliable edge for shoes to latch onto when walking.

In the winter months, aluminum non-slip stair nosings can be easily cleared of ice and snow without fear of damage by using a snow shovel (without a steel edge). We suggest clearing the steps of snow by starting at the bottom of the stairs and working your way up to the top. This method ensures that you are always stepping on a tread and nosing that is clear of snow and ice.

The installation of the Non-Slip Nosings on concrete stairs is straightforward with only an electric drill and concrete anchor pins required. HandiTreads Non-Slip Nosings are guaranteed to last a lifetime in residential environments, so no maintenance is required after installation.

Because HandiTreads aluminum Non-Slip Nosings are a lifetime solution with only a one-time installation and maintenance, their initial cost may be higher than other products marketed as slip and fall prevention. However, when calculated over a three to five year performance period, the investment in HandiTreads is almost always the most cost-effective solution.

Expert Insight: HandiTreads Non-Slip Nosings are precision-engineered in the USA using corrosion-resistant aluminum that withstands decades of freeze-thaw cycles, salt exposure, and foot traffic. Their patented traction button design clears water, frost, and debris instantly, ensuring stable footing in all conditions. That’s why building inspectors, ADA consultants, and contractors consistently recommend HandiTreads as the permanent fix for slippery concrete stairs.

Total Score: A-

Effectiveness: A

Installation & Maintenance: A

Durability: A

Initial Price: C

Long-Term Value: A

Handi-Treads: A-

Unlike grit paint, rubber mats, or other solutions, the aluminum HandiTreads can be cleared with a snow shovel, as long as it doesn’t have a sharp steel edge.

Like the aluminum Non-Slip Nosings, the installation of HandiTreads on concrete stairs requires only an electric drill and concrete anchor pins. HandiTreads are guaranteed to last a lifetime in residential environments, so no maintenance is required after installation.

Because HandiTreads are a lifelong safety solution with only a one-time installation and maintenance, their initial cost may be higher than other anti-slip products. However, when calculated over a three to five year performance period, the investment in HandiTreads is almost always the most cost-effective solution.

Total Score: A-

Effectiveness: A

Installation & Maintenance: A

Durability: A

Initial Price: C

Long-Term Value: A

Rubber or Door Mat Style Treads: C-

While doormat-style and rubber treads can be used on raw concrete stairs, their lack of structural rigidity can lead to significant hazards. The only safe way to affix the rubber or fiber treads to concrete is with the use of lags and screws. Because mats have no self-sustaining structure, the corners of the doormat or rubber treads can pop up if any of the lags or screws give way, creating a dangerous slip and fall hazard. This lack of structural rigidity and unpredictable lags also allows water to seep into the drilled holes, degrading the contact further.

Both rubber and doormat-style treads can be somewhat effective in wet and winter weather if they are kept free of snow. Care must be taken when using a snow shovel with rubber treads as even a plastic blade can damage the rubber, requiring further maintenance. Snow can be removed from doormat-style treads with a shovel fairly easily as long as care is taken not to lodge the shovel under the edge of the tread.

Some rubber stair treads suggest that it is acceptable to use adhesive caulk to secure rubber or doormat treads to painted concrete. This is poor advice as concrete is prone to spalling, which is similar to paint peeling. Therefore, rubber treads affixed with adhesive caulk do not offer a long-lasting solution and may also further damager your concrete steps.

There is no maintenance that can be performed on rubber or doormat-style stair treads to increase their lastability, so as time goes on, they begin to decline in form or function. Deeply patterned or cut treads also collect dirt in the gaps and require using a leaf blower or water during the summer in order to retain some sort of anti-slip prevention. Depending upon the thickness and quality of the material, you can expect rubber or doormat-style treads to last only 2 to 3 years. Because they only last a few years and are not manufactured to be a lifetime solution, rubber or doormat-style tread replacements will end up costing more than the initial cost of a permanent solution like HandiTreads.

Total Score: C-

Effectiveness: C

Installation & Maintenance: D

Durability: C

Initial Price: B

Long-Term Value: C

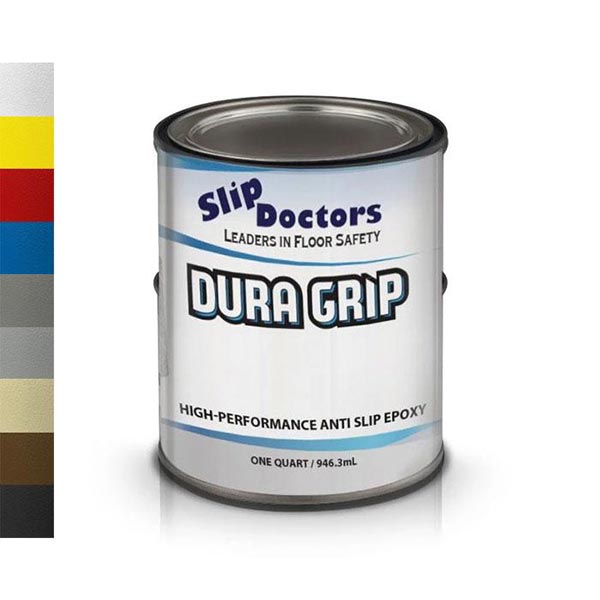

Grit Paint: C+

Grit paint can reduce slipperiness on raw concrete stairs in most environmental conditions. Grit paint can improve the safety of a deck or porch if (1) it’s a high-quality enamel or epoxy paint, (2) it’s applied meticulously, and (3) it’s maintained properly.

Like grit tape, non-slip paints include an aggregate that creates traction. The best anti-slip paints contain aluminum oxide or carborundum that, while encapsulated in the paint, create a rough, slip-resistant surface. Grip paint can be effective for wet weather, frost, or a minimal dusting of snow.

Non-slip paints on exterior surfaces are, by and large, maintenance-free. However, if you live in a location that receives a lot of snow, you need to be very careful not to aggressively shovel the stairs painted with grit paint. While the epoxy or enamel coating is durable under normal foot traffic, it is no match for an aluminum or even plastic snow shovel. Once you start to scrape away the thin paint layer covering the aggregate, the system will quickly degrade and will no longer properly prevent slips and falls.

The cost of a high-quality grit paint can run between $60 and $120 a gallon. In addition, there is the consumable cost of paintbrushes or rollers, trays, sandpaper, masking tape, and drop cloths. When properly applied, grit paint can be expected to last only 2 to 4 years on raw concrete steps, which creates another recurrent expense. With all costs factored in and depending upon the number of stairs, grit paint can be one of the most expensive solutions.

Total Score: C+

Effectiveness: B

Installation & Maintenance: D

Durability: C

Initial Price: C

Long-Term Value: B

Frequently Asked Questions About Slippery Concrete Steps

How do I make my concrete steps less slippery in winter?

Install aluminum HandiTreads or non-slip nosings. Their raised traction buttons and edge grip push away water, frost, and snow—keeping your stairs safe year-round.

What’s the best non-slip coating for concrete stairs?

High-quality epoxy or enamel grit paint with aluminum oxide aggregate can improve traction, but it wears out faster than permanent aluminum treads.

Do rubber stair treads work on outdoor concrete steps?

They can offer short-term traction, but rubber warps, traps water, and deteriorates in UV exposure. They’re better suited for temporary indoor use.

Can I install HandiTreads or nosings myself?

Yes. Both products attach easily with a drill and concrete anchor pins—no special tools or surface prep required.

Are HandiTreads and nosings ADA compliant?

Yes. Their low profile (under ¼ inch) and beveled edges meet ADA guidelines for surface transitions on accessible routes.

How long do aluminum treads last compared to paint or rubber?

Grit paint typically lasts 2–4 years and rubber treads about 2–3 years. HandiTreads and aluminum nosings are permanent, maintenance-free solutions backed by a lifetime warranty.